NEED A TESTED AND CERTIFIED PRODUCT?

Tests offered by QUALILAB relate to

- Mirror goniophotometer: photometric characterisation of luminaires and light sources – light distributions

- Photometric tunnel: photometric characterization of traffic lights, building site lamps, variable message panels, maritime and airport lights and homologation of automotive lighting devices

- Photobiological safety: characterization of risk-group in accordance with EN62471 and IEC/TR62778

- Radiometry/colour measurement: spectral sources measurements, colour measurements, CCT, CRI

- EMC testing: immunity and emission test of electrical and electronic devices

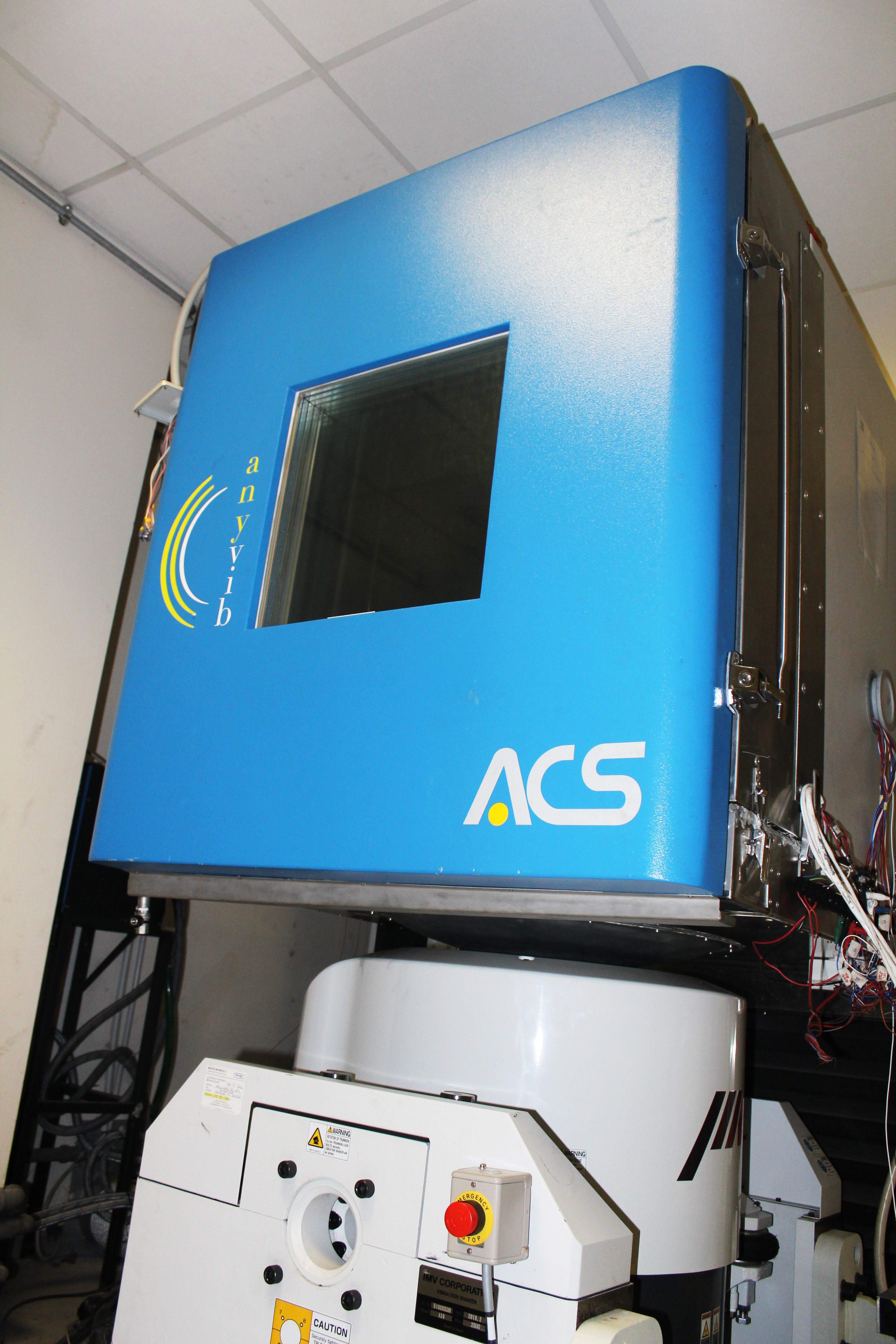

- Vibrations: vibration systems, also with slip table and simultaneous temperature and humidity profiles

- Climate testing: climatic chambers and thermal shock

- Ageing: corrosions and light ageing (solar simulation)

- IP testing: according to civil and industrial or automotive standards

- Wheels: testing mechanical testing on car rims

- UNI10772: OCR systems audits

- Acoustic testing: semianechoic chamber for acoustic tests and sound level meters with class 1 spectrometer

Mirror based Goniophotometer

Why a mirror based photogoniometer? Luminary remains in mounting position during test – not variating its thermal characteristics, with a high angular resolution.

Mirror based Goniophotometer LMT GO-DS 2000 for photometric light distribution (LDT , IES), luminous flux (lm), luminous efficiency (lm/W) and light pollution in accordance with various regional laws.

Angular resolution: 0,1°

Samples: up to 2000 mm in diameter and 50 kg of maximum weight

Main standards: LM79, LM82, TM21, EN13032-1, EN13032-4

Photometric Tunnel

Goniophotometer LMT GO-H 1200 or light intensity distribution (cd), illuminance (lx) and colour.

Measurement system for flashing lights LMT SF100 – effective intensity (cd).

System for retroflection measurement – CIL (mcd/m2, mcd/m2/lx) LMT RETRO 2000.

System for luminance measurement (cd/m2) LMT L1009.

Norms and standards: tests performed in accordance with automotive manufacturer standards, ECE ONU regulations for lighting devices (front and rear lamps, reflectors, warning triangles, flashing lights and more), international automotive standards, American standards FMVSS 108 and SAE, standards for warning and alarm devices ( CPR 305/201/CE).

Photobiological Safety

Evaluation of light-emitting hazard, in particular for photobiological risk (UV risks actinic skin and eye, UV-eye, blue light small source, IR eye, skin thermal, blue light, retinal thermal, thermal retinal weak visual stimulus).

Norms and standards: IEC EN 62471-1 (photobiological safety), IEC/TR 62778, European directive on safety at work 89/391/CE and Legislative Decree 81/2008 for the ‘protection of workers from the risks of exposure to artificial optical radiation’.

Radiometry/Colour Measurement

Radiometric and colorimetric measurements with double monochromator spectrometer from 200 nm to 3000 nm (UV – VIS – IR).

Testing measures: radiance and spectral irradiance

Derivative measurements: CCT – colour temperature, CRI – colour rendering index, colorimetric coordinates.

Vibrations

Shaker up to 30 kN with slip table and combined climatic chamber (-70 °C to +180 °C).

Shaker out chamber 10 kN.

Shock, random, sine, multisine and sine on random testing.

Climate Testing

QUALILAB arranges climate testing with:

- 5 oven (up to 220 °C).

- 1 climatic chamber (-70 °C to +180 °C).

- 7 climatic chambers (with humidity control) with a temperature range from -70 °C to +180 °C.

- 1 thermal shock (-70 °C to +180 °C).

- 1 humidistat.

- test chamber (2200x3500x2500 mm) up to 60 °C.

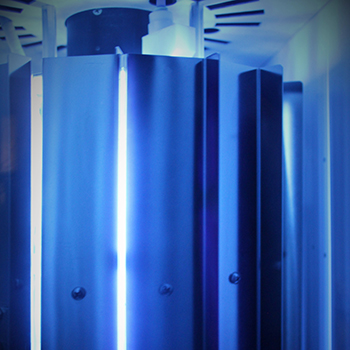

Ageing Testing

Neutral salt spray chamber for corrosion testing, with capacity for 1200 litres.

N. 2 Light ageing chambers (XENON source).

IP Testing

- Dust test chamber for IP5X, IP6X (2400x2400x2400 mm).

- Instruments for IP1X, IP4X test – against ingress of foreign solids.

- Water spray test chamber IPX3, IPX4.

- Water spray test IPX5, IPX6, IP9K.

- System for immersion test IPX7, IPX8.

- Dust test chamber (Portland cement and Arizona dust) in accordance with SAE, JIS, ASTM.

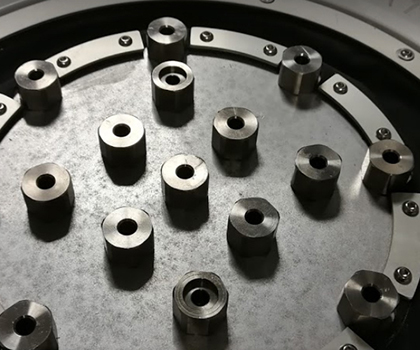

Wheels Testing

QUALILAB has all necessary instruments to perform resistance testing on wheels like bending moment tests, impact tests, rim-rolling tests and corrosion tests in-house.

KBA approved our laboratory for the directive StVZO par.30 expl.42 and for the homologation in accordance to regulation ECE ONU R124.

On request, we can test rims according to the specifications of the manufacturers.

Our equipment:

- bending moment machine (from 14’’ to 24’’)

- impact tester

- rim-rolling machine

Standards and regulations:

- regulation ECE ONU R124

- directive StVZO par.30 expl.42 (German federal motor vehicle standard)

- manufacturer standards

- ISO 7141, SAEJ175

UNI10772 OCR systems

QUALILAB obtained the accreditation by ACCREDIA for the UNI10772 standard about verification and certification of automatic plate recognition systems.

Acoustic Testing

Semianechoic chamber for acoustic tests and sound level meters with class 1 spectrometer.

Our Equipment:

- Semi-Anechoic Chamber

- Equipment compliant with CISPR16 (antennas, LISNs, CDNs)

- System for Emission tests in the range between 9 kHz and 6 GHz

- radiated, condotted, Stripline 90 Ω method

- System for Immunity tests in the range between 10 kHz and 6 GHz

- ALSE method, BCI method, Stripline 90 Ω method

- Max EM field 300 V/m, Max injection current 300mA

- System to perform ISO pulses test, on supply lines

- System to perform ISO pulses test, on signal lines (CCC, DCC, ICC)

- System for ESD immunity test, with a maximum discharge level of 30 kV

- System for magnetic immunity for automotive components

- System for Harmonics and Flickers verification

- System for Power fails/ Burst/Surge (Max. 5 kV) verification

- Optical transceiver for CAN, LIN, Ethernet automotive communication

General standards and Specifications:

- Automotive:

- ECE R10 Device

- ECE R97 Alarm systems

- ECE R116 Alarm and anti-thief systems

- ISO 7637-2 Immunity on supply lines

- ISO 7637-3 Immunity on signal lines

- CISPR25 Emission tests

- ISO 11452 Immunity tests

- ISO 10605 ESD tests

- ISO 16750 Electrical tests

- LV124 Pulses

- Specific Manufacturer standards, for example: BMW GS 95002, CNH ESN0310, Ducati Standard DMH 34-03.001 Ed. 4.0, FCA CS-00056, McLaren MSL.03.04.0001, Volkswagen VW80000 e TL81000, and much more

- Industrial/Luminaire:

- EN 55015 Emission tests

- EN 55022 Emission tests

- EN 55032 Emission and Immunity tests

- EN 61000 Series: Radiated and Conducted Immunity, Immunity to Burst/Surge/Power Fail

Tests offered by QUALILAB relate to:

Why a mirror based photogoniometer? Luminary remains in mounting position during test – not variating its thermal characteristics, with a high angular resolution.

Mirror based Goniophotometer LMT GO-DS 2000 for photometric light distribution (LDT , IES), luminous flux (lm), luminous efficiency (lm/W) and light pollution in accordance with various regional laws.

Angular resolution: 0,1°

Samples: up to 2000 mm in diameter and 50 kg of maximum weight

Main standards: LM79, LM82, TM21, EN13032-1, EN13032-4

Goniophotometer LMT GO-H 1200 or light intensity distribution (cd), illuminance (lx) and colour.

Measurement system for flashing lights LMT SF100 – effective intensity (cd).

System for retroflection measurement – CIL (mcd/m2, mcd/m2/lx) LMT RETRO 2000.

System for luminance measurement (cd/m2) LMT L1009.

Norms and standards: tests performed in accordance with automotive manufacturer standards, ECE ONU regulations for lighting devices (front and rear lamps, reflectors, warning triangles, flashing lights and more), international automotive standards, American standards FMVSS 108 and SAE, standards for warning and alarm devices ( CPR 305/201/CE).

Evaluation of light-emitting hazard, in particular for photobiological risk (UV risks actinic skin and eye, UV-eye, blue light small source, IR eye, skin thermal, blue light, retinal thermal, thermal retinal weak visual stimulus).

Norms and standards: IEC EN 62471-1 (photobiological safety), IEC/TR 62778, European directive on safety at work 89/391/CE and Legislative Decree 81/2008 for the ‘protection of workers from the risks of exposure to artificial optical radiation’.

Radiometric and colorimetric measurements with double monochromator spectrometer from 200 nm to 3000 nm (UV – VIS – IR).

Testing measures: radiance and spectral irradiance

Derivative measurements: CCT – colour temperature, CRI – colour rendering index, colorimetric coordinates.

Immunity and emission test of electrical and electronic devices.

Our Equipment:

- Semi-Anechoic Chamber

- Equipment compliant with CISPR16 (antennas, LISNs, CDNs)

- System for Emission tests in the range between 9 kHz and 6 GHz

- radiated, condotted, Stripline 90 Ω method

- System for Immunity tests in the range between 10 kHz and 6 GHz

- ALSE method, BCI method, Stripline 90 Ω method

- Max EM field 300 V/m, Max injection current 300mA

- System to perform ISO pulses test, on supply lines

- System to perform ISO pulses test, on signal lines (CCC, DCC, ICC)

- System for ESD immunity test, with a maximum discharge level of 30 kV

- System for magnetic immunity for automotive components

- System for Harmonics and Flickers verification

- System for Power fails/ Burst/Surge (Max. 5 kV) verification

- Optical transceiver for CAN, LIN, Ethernet automotive communication

General standards and Specifications:

- Automotive:

- ECE R10 Device

- ECE R97 Alarm systems

- ECE R116 Alarm and anti-thief systems

- ISO 7637-2 Immunity on supply lines

- ISO 7637-3 Immunity on signal lines

- CISPR25 Emission tests

- ISO 11452 Immunity tests

- ISO 10605 ESD tests

- ISO 16750 Electrical tests

- LV124 Pulses

- Specific Manufacturer standards, for example: BMW GS 95002, CNH ESN0310, Ducati Standard DMH 34-03.001 Ed. 4.0, FCA CS-00056, McLaren MSL.03.04.0001, Volkswagen VW80000 e TL81000, and much more

- Industrial/Luminaire:

- EN 55015 Emission tests

- EN 55022 Emission tests

- EN 55032 Emission and Immunity tests

- EN 61000 Series: Radiated and Conducted Immunity, Immunity to Burst/Surge/Power Fail

Shaker up to 30 kN with slip table and combined climatic chamber (-70 °C to +180 °C).

Shaker out chamber 10 kN.

Shock, random, sine, multisine and sine on random testing.

QUALILAB arranges climate testing with:

- 5 oven (up to 220 °C).

- 1 climatic chamber (-70 °C to +180 °C).

- 7 climatic chambers (with humidity control) with a temperature range from -70 °C to +180 °C.

- 1 thermal shock (-70 °C to +180 °C).

- 1 humidistat.

- test chamber (2200x3500x2500 mm) up to 60 °C.

Neutral salt spray chamber for corrosion testing, with capacity for 1200 litres.

N. 2 Light ageing chambers (XENON source).

- Dust test chamber for IP5X, IP6X (2400x2400x2400 mm).

- Instruments for IP1X, IP4X test – against ingress of foreign solids.

- Water spray test chamber IPX3, IPX4.

- Water spray test IPX5, IPX6, IP9K.

- System for immersion test IPX7, IPX8.

- Dust test chamber (Portland cement and Arizona dust) in accordance with SAE, JIS, ASTM.

QUALILAB has all necessary instruments to perform resistance testing on wheels like bending moment tests, impact tests, rim-rolling tests and corrosion tests in-house.

KBA approved our laboratory for the directive StVZO par.30 expl.42 and for the homologation in accordance to regulation ECE ONU R124.

On request, we can test rims according to the specifications of the manufacturers.

Our equipment:

- bending moment machine (from 14’’ to 24’’)

- impact tester

- rim-rolling machine

Standards and regulations:

- regulation ECE ONU R124

- directive StVZO par.30 expl.42 (German federal motor vehicle standard)

- manufacturer standards

- ISO 7141, SAEJ175

QUALILAB obtained the accreditation by ACCREDIA for the UNI10772 standard about verification and certification of automatic plate recognition systems.

Semianechoic chamber for acoustic tests and sound level meters with class 1 spectrometer.